LOREEN ... / 3: The Loreen series of the third generation has been specially designed for optimal control via a touchscreen control panel, which is unique in our industry. The unbreakable glass surface can also be operated with gloves and shows you the important parameters of the machine. All settings can be made via the display. Especially in areas with customer traffic, this is an eye-catcher, but also in the normal production area, the Loreen ... - 3 stands out with its hygienic design. This version is available in the models Lorren 15/3, Loreen 24/3 and Loreen 60/3

Continuously tempering

Perfect basis for your quality products

Continuous tempering is the most comfortable and successful way to give chocolate the shine your product deserves later. The machines of the "Loreen" series and the corresponding ancillary equipment have been specially designed to save you and your employees time and money and to provide you with perfectly tempered chocolate mass at all times!

Challenge

Producing a high-quality and at the same time inexpensive tempering machine is a demanding task. There are many simple and cheap systems on the market. CBCMAC initially focuses on a technically perfect and durable machine without any significant compromises. Only then is it attempted to produce these cost-effectively in series and thus to create an extremely good price-performance ratio. This is best done with the series "LOREEN". This series is available in 2 versions and in 3 tank sizes with 15 kg, 27 kg and 75 kg content.

The two user interfaces

Highlights that convince:

- Continuous circulation temperature control

- Tank with modernized heating system for quick dissolution of the chocolate and crystals

- Conveyor screw with heat and cold circulation

- Constantly fresh tempered chocolate

- Tempering time only about 15-20 minutes

- State-of-the-art cooling with refrigeration unit and closed water circuit

- New, state-of-the-art control for an even finer tempering degree

- Stainless steel frame

- Stainless steel screw conveyor

- Simple user interface with few buttons

- Optionally with membrane keyboard or modern touch screen

- Dosing function for pouring a predetermined amount of chocolate

- Dosing by footswitch with control

- Easy emptying

- Easy fast access to the inside part of the machine

- Additional advanced heating elements in the machine

- Includes removable vibrating table to vibrate air bubbles in the mold

- Includes scraper on vibrating table when making bowls

- Loreen 24 and Loreen 60 now with enlarged shelves for up to 2 x 3 forms (!)

- The small Loreen 15 can also be retrofitted with a stall system

- Complete machine on wheels

- 2 wheels with parking brake

- Small space requirement due to vertical arrangement of tank and cooling unit

- Only low power consumption

- Expandable systems, dosing systems, coating systems, powdering, etc.

- Very interesting priceNew text

Technical specifications:

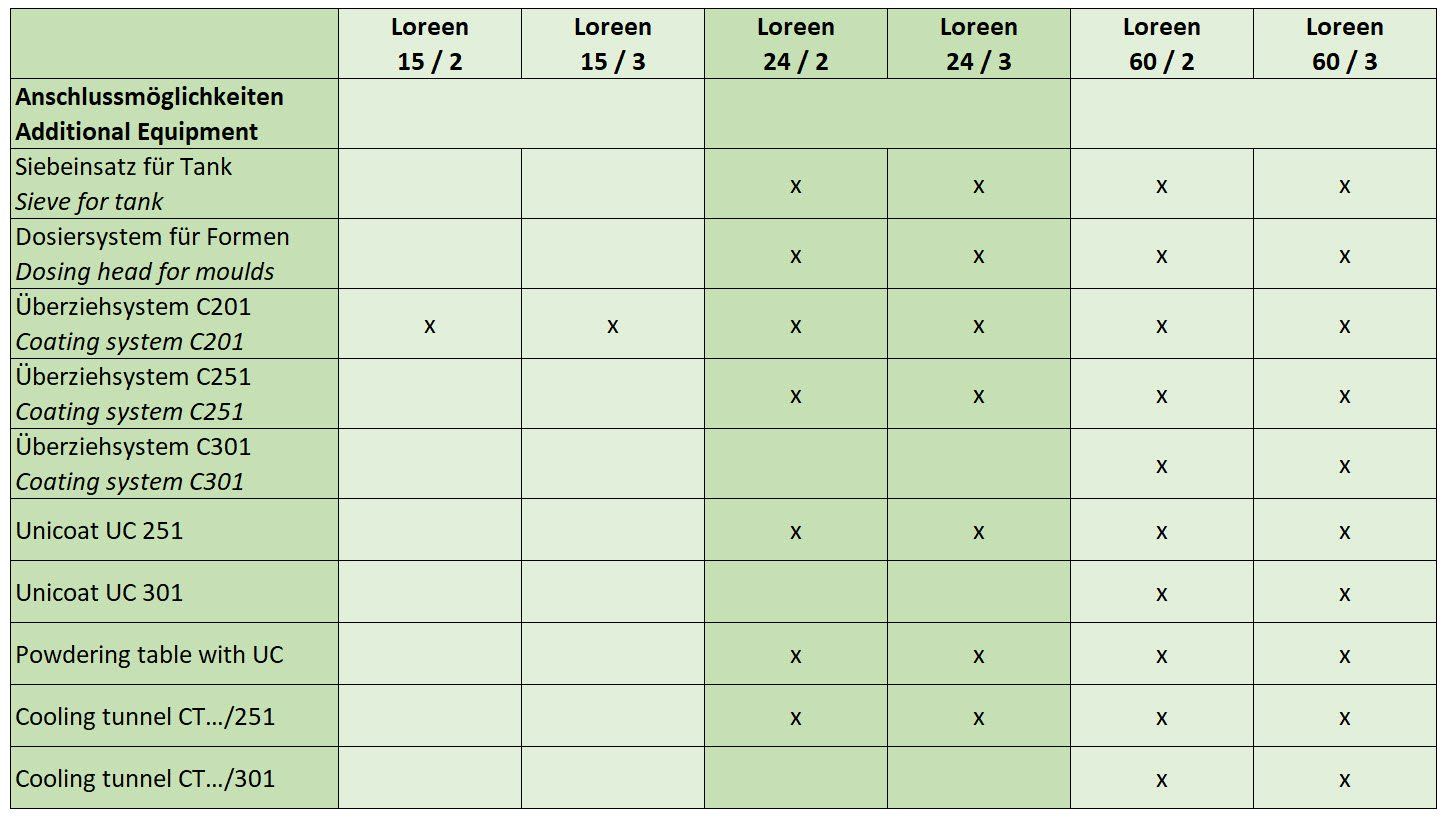

Supplement options: